JAVA Metal always choose the high quality raw materials to ensure the supply of quality products from the source.

The punched aluminum veneer is not only dust-proof and moisture-proof, fire-retardant and flame-retardant, wear-resistant and weather-resistant, and has a long service life, but also has good plasticity, which can realize many amazing hollow-shaped creative decorations. field and the effect is not bad.

Application space of punched aluminum veneer:

1. Exterior walls, beams, and balconies of buildings. The aluminum curtain wall is durable; the beams and columns can be punched with cladding aluminum veneer, while the fluorocarbon punched aluminum veneer is often used for canopies and has good corrosion resistance.

2. Widely used in large public facilities, such as airports, stations, hospitals, etc. These large public places have relatively high requirements on building decoration materials.

3. In addition to the above places, conference rooms, opera houses, stadiums, reception halls, etc., the use of perforated aluminum veneer in these occasions mainly considers decorative and sound-absorbing effects.

The advantages of punched aluminum veneer:

1. It can make the building look full of art and improve its grade;

2. The punching hole can make the room a ventilated and bright light effect;

3. Light weight, easy to transport and install, and a recyclable metal material. It meets the requirements of modern society for green building materials.

What should be paid attention to in the punching process of punching aluminum veneer?

1. Hole diameter

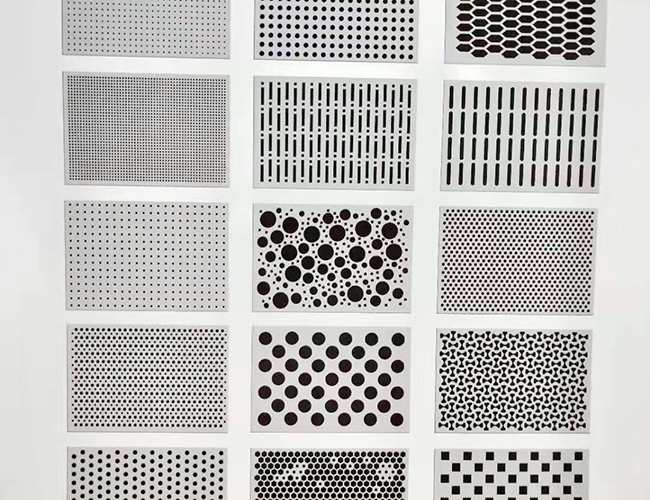

The aperture of the punched aluminum veneer, that is, the hole diameter. The common hole types of punched aluminum veneer are round holes, square holes, oblong holes, hexagonal holes, fish scale holes, etc. The common arrangements are straight and staggered. The common apertures of punched aluminum veneer are 3mm, 4mm, 5mm, and 6mm.

In addition, punched aluminum veneer with other hole types and apertures can also be customized, because punched aluminum veneer itself is a non-standard product, so the manufacturer will mainly produce and process according to the drawings provided by customers.

2. Hole distance

The hole spacing of the punched aluminum veneer, that is, the hole spacing.

The hole distance of the punched aluminum veneer is mainly determined according to the purpose of the punched plate and the size of the aperture. Generally speaking, the hole spacing specification of punched aluminum veneer used for exterior wall decoration can be a little larger than that of other punched aluminum veneer. The hole spacing of punched aluminum veneer will change with the size of the aperture. Generally, the smaller the aperture, the smaller the spacing.

3. Punching rate

The punching rate of punched aluminum veneer, that is, the punching density, can be calculated by the formula of punching rate = punching area / area of the whole punching aluminum veneer. The hole diameter and hole distance together determine the punching rate of the punched aluminum veneer. The punching rate of punched aluminum veneer has a crucial impact on the punching quality of aluminum veneer.

The following are some reference values for the punching rate of punched aluminum veneer in different scenarios

The punching rate of aluminum veneer for curtain wall and ceiling decoration is preferably 15%-35%, which is more aesthetic and sound-absorbing; while the punching rate of perforated aluminum veneer for exterior wall decoration can reach 50%. When the punching rate is large, the strength and deformation resistance of the aluminum plate should also be considered, especially when it is used in outdoor curtain wall projects. For example, when the punching rate is greater than 50%, in order to ensure the flatness and effect of the board surface, an aluminum plate with a thickness of less than 3.0mm cannot be used.

Hole diameter, hole distance and punching rate are the three elements of punching process of punching aluminum veneer. The price of punched aluminum veneer with different apertures, hole spacing and punching rate is also different, because the consumables and processing difficulty of aluminum veneer are also different. Selecting the appropriate hole diameter, hole spacing and punching rate is the key to making a punched aluminum veneer.

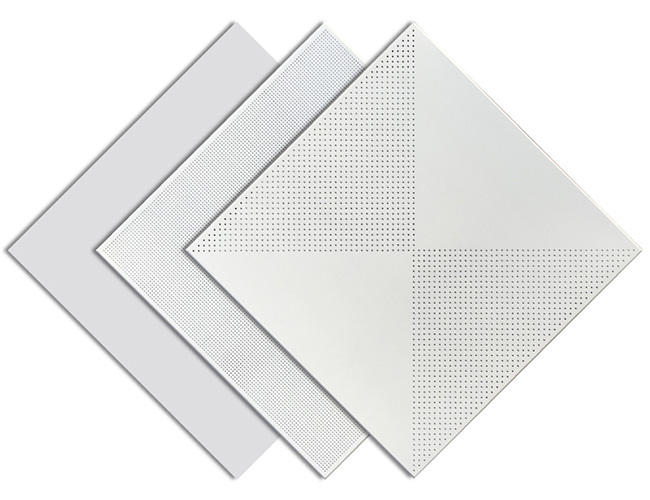

The standard, size, color and surface treatment can be customized according to the customer request.

Main Advantages

Light weight, good stiffness, high toughness and high intensity

durability and strong corrosion resistance.

Best process technology. JAVA Metal using technics of processing before spraying, and aluminium sheet can be processed into various complex geometries such as plane, arc and sphere.

Coat uniformity, color diversified. Our advanced spraying technology makes the attachment between the paint and aluminum sheet become uniform and consistent, and the color diversification give your a large choice space.

Anti-staining and easy to clean and maintain.

Convenient and fast of installation and contruction.

Recyclable and environmental. Aluminium sheet is 100% recyclable and it is different from glass, stone, ceramics and other decorative materials.