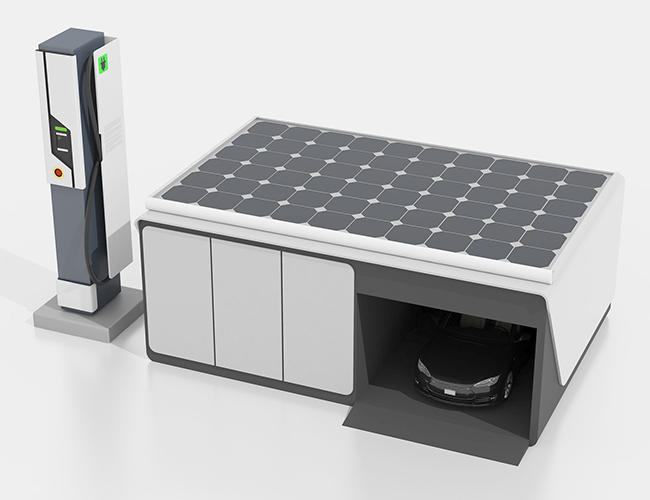

JAVA Metal has several sets of advanced sheet metal processing equipment, which can customize and process all kinds of energy storage cabinet.

Energy storage refers to the process of storing energy through a medium or device and releasing it when needed. In fact, energy storage itself is not an emerging technology, but from an industrial perspective, it is in its infancy and development stage. Energy storage technology is a key node for the future energy system to have flexible, inclusive and balanced functions.

Energy storage technology is classified according to the storage medium, which can be divided into mechanical energy storage, electrical energy storage, electrochemical energy storage, thermal energy storage and chemical energy storage.

Why is energy storage so hot?

Energy storage itself is not an emerging technology, but it seems that the concept of energy storage has become popular overnight? Its root is environmental protection.

In September 2020, my country pledged to achieve carbon peaking in 2030 and carbon neutrality in 2060, while Western countries have achieved carbon neutral emission reduction targets by 2050. Now all countries have reached a consensus on carbon emissions and have formulated very strict standards. In the future, whether a product can thrive, the first priority is not whether it is easy to use, but whether it is environmentally friendly.

In the process of replacing fossil energy with new energy, energy storage technology can be said to be the core of the new energy industry revolution, and the energy storage market has also ushered in explosive growth, which will inevitably lead to fierce competition in the new energy market.

Under the premise that the energy storage technology is so popular, the energy storage cabinet will also usher in market opportunities. The role of the energy storage cabinet is to play a good role in protection against dust, water, fire and constant temperature.

Precautions for processing energy storage cabinets:

1. The expansion method should be combined, and it is convenient to save materials and processability.

2. Reasonably choose the method of open space and wrapping, t=0.2 below 2.0, t=0.5 below 2-3, and the long side wraps the short side (door panels).

3. Reasonably consider the shape standard of public service: negative difference to the end, positive difference to the end, hole shape standard: positive difference to the end, negative difference to half.

4. Burr direction.

5. Draw a profile in the direction of tooth extraction, riveting, tearing, punching and bump (bag).

6. Check the material, plate thickness and plate thickness public service.

7. Special viewpoint for sheet metal chassis processing, bending viewpoint radius (generally r=0.5) to test and open.

8. Emphasis should be placed on checking for easy mistakes (similar asymmetry).

9. Where there are more standards, an enlarged map should be added.

10. The local spraying must be marked.

11. The coating on the surface of the sheet metal chassis must be uniform, and there shall be no hanging or exposed bottom.

12. The logo should be intact, clear, durable and reliable, and the serial number of the logo should not be lost.

13. The panels of the sheet metal chassis should be flat, free of deformation and distortion, and the openings of the cabinet doors should be uniform and regular.

14. The standard should meet the requirements, and the error should not be too large.

JAVA Metal has a number of imported advanced equipment and a complete set of processing technology. The company specializes in the production of self-service equipment cabinets, network cabinets, communication cabinets, power cabinets, monitoring cabinets and energy storage cabinets. The company has passed the ISO9001-2008 international quality system certification, and is a sheet metal processing manufacturer integrating R&D, production, processing and after-sales service.

Main Advantages

1.The saw-cut length error is small

2.With the excelsior detail processing, there are no burr and flashing of the processing site.

3.There are no chromatic difference, no bubble and free from pinhole porosity of the external surface treatment.