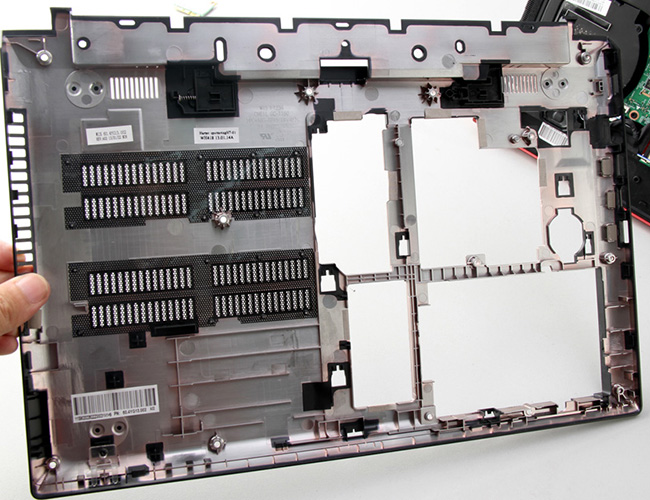

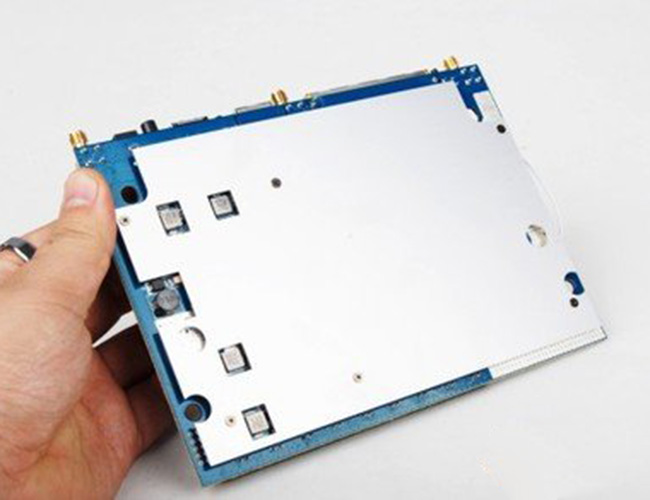

JAVA Metal has several sets of advanced sheet metal processing equipment, which can customize and process all kinds of instrument Backcover.

Precision instruments refer to the equipment and devices used to generate and measure precise quantities, including observation, monitoring, measurement, verification, recording, transmission, transformation, display, analysis, processing and control of precise quantities. Precision instruments are an important branch of instrumentation.

According to the different measurement objects, precision instruments can be divided into the following categories:

1. Geometric precision instruments

It mainly includes precision instruments for detecting various geometric quantities, such as vertical goniometers, laser interferometers, theodolites, three-coordinate measuring machines, roundness meters, profilometers, scanning tunneling microscopes and other measuring instruments.

2. Thermal volume precision instrument

It mainly includes precision instruments for temperature, humidity, pressure and flow detection, such as various barometers, vacuum gauges, multi-wavelength temperature measuring instruments, flow meters and altimeters.

3. Mechanical precision instruments

It mainly includes various force measuring instruments, strain gauges, acceleration and velocity measuring instruments, torque measuring instruments, vibration measuring instruments, universal material testing machines and Brinell hardness testers.

4. Time and frequency precision instruments

It mainly includes various timing instruments and meters, atomic clocks, time and frequency measuring instruments, etc.

5. Electromagnetic precision instruments

It is mainly used to measure various electric quantity and magnetic quantity, such as ammeter, voltmeter, power meter, resistance measuring instrument, capacitance measuring instrument, electrostatic instrument and magnetic parameter measuring instrument, etc.

6. Radio precision instruments

It mainly includes oscilloscope, signal generator, phase measuring instrument, spectrum analyzer and dynamic signal analyzer.

7. Optical and acoustic precision instruments

It mainly includes spectrometer, photometer, colorimeter, laser parameter measuring instrument, optical transfer function measuring instrument, noise measuring instrument and sonar measuring instrument.

8. Precision instruments for ionizing radiation

It mainly includes various radioactivity, nuclide measurement, X and λ and other ray measurement instruments.

What components are precision instruments made of? There are many kinds of precision instruments and different structures. For the precision instrument used for measurement, its structure can be divided into eight functional components such as reference, feeling conversion, conversion amplification and transmission, aiming/reading, data processing, display recording, drive control, and mechanical structure. But it does not mean that a precision instrument must contain the above-mentioned eight functional components, but should be selected according to the requirements of the instrument function.

With more and more precision instruments used in all walks of life in life, the demand for mechanical structure is also increasing. The mechanical structure includes bases, brackets, backplanes, guide rails, workbenches, shafts and other components. Such as fine-tuning, locking, limiting, protection and other mechanisms. It is an indispensable part in the instrument, and its accuracy sometimes plays a decisive role in the influence of the instrument accuracy.

JAVA Metal has a number of advanced sheet metal processing equipment, and has a complete set of sheet metal processing processes: laser cutting, bending, riveting, welding, grinding and polishing and surface treatment, and can customize various types of precision instruments. required mechanical parts. Materials can be selected from cold-rolled sheet, hot-rolled sheet, galvanized sheet, copper sheet, aluminum alloy, stainless steel and other materials. The whole process design can also be carried out according to pictures or sketches required by customers. Welcome to consult!

JAVA Metal can provide the customised processing services of cold-rolled plate, hot-rolled plate, galvanized plate, copper plate, aluminum alloy, stainless steel and other materials.

Main Advantages

1.The saw-cut length error is small

2.With the excelsior detail processing, there are no burr and flashing of the processing site.

3.There are no chromatic difference, no bubble and free from pinhole porosity of the external surface treatment.