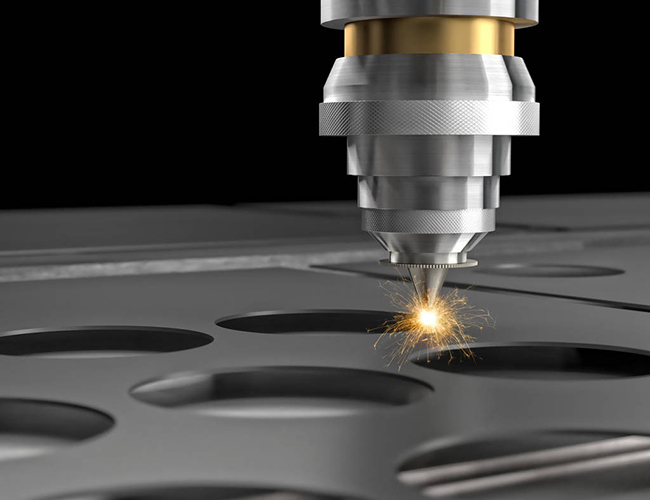

Fiber laser cutting machine generates powerful laser beam by a laser source, match with the numerical control system to auto, quick and high precision sheet cutting.

This hi-tech machine integrates advanced fiber laser technology, numerical control and precision machinery technology.

The laser cutting processing technology is realized by using the laser beam to move continuously on the surface of the accessories. The laser beam in this kind of work has good guidance and good correlation, and its cutting ability density is good. The following is an introduction to the specific laser cutting process.

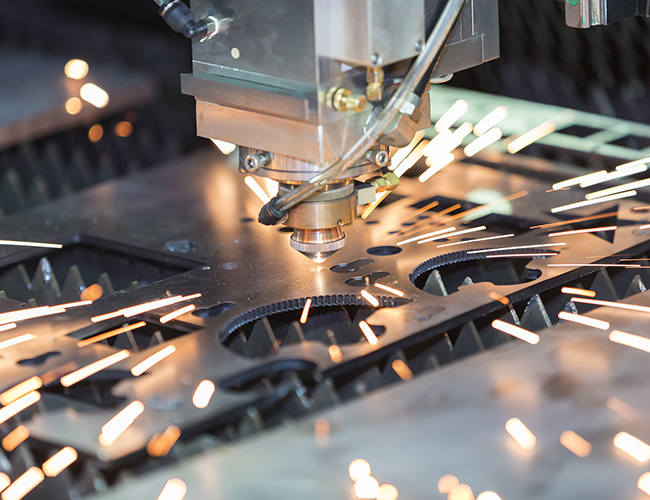

There are three types of laser cutting processes:

1. The fusion cutting method is to irradiate the laser incident light speed into the plate. When the laser power reaches a certain critical value, the local area will be melted, so as to achieve the cutting effect.

2. Vaporization cutting uses a high power density laser to heat the processing material to avoid slag burrs formed by melting caused by heat conduction. Some materials evaporate and disappear after evaporation, and the edges are more beautiful.

3. Oxidation cutting refers to the thermal processing caused by blowing oxygen in the nozzle to ignite the laser, and the oxygen undergoes a violent chemical reaction; for brittle materials that are easily damaged by heat, the cutting can be controlled at high speed by heating the laser beam, resulting in a large thermal gradient in the area and mechanical The deformation is severe, causing the material to crack, also known as controlled fracture cutting.

Features of laser cutting processing:

1. The speed is fast, the incision is smooth and flat, and generally no follow-up processing is required; the cutting heat-affected zone is small, the plate deformation is small, and the slit is narrow;

2. The incision has no mechanical stress and no shearing burr;

3. High machining accuracy, good repeatability, and no damage to the surface of the material;

4. Numerical control programming can process any plan, and can cut the whole board with large format without opening the mold, which is economical and time-saving.

5. There are many materials that can be cut by the laser, including non-metallic plates such as glass, wood, plastic, and various metal materials such as stainless steel, carbon steel, alloy steel, and aluminum plates.

6. Pulse laser is suitable for metal materials, and continuous laser is suitable for non-metal materials. The latter is an important application field of laser cutting technology.

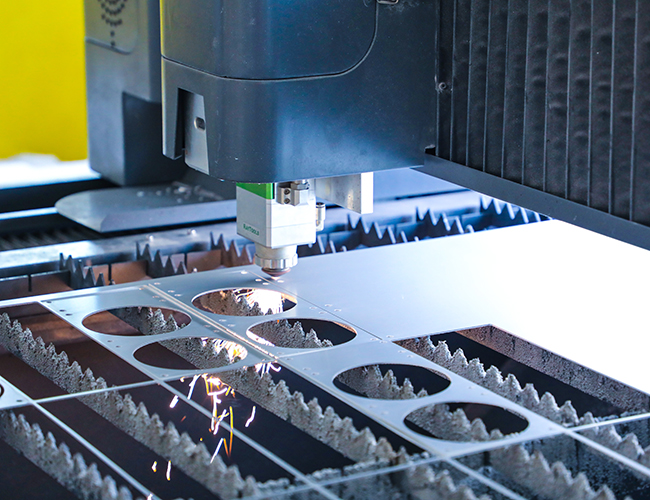

Main Advantages

High quality of the slicing

High production

High precision

Increasing cutting speed

Non-contact type cutting

It can cut multiple cutting materials